Constraint Management & G100 Export Limitation in Practise

When undertaking G100 constraint management or active network management (ANM), one of the critical elements is how to understand what an export limitation or constraint management system is doing to ensure that you stay within the regulated limits.

I thought I’d write a short piece to try and explain, using images from our Asset Management Platform called GridLENZ.

In brief, an export limit interacts algorithmically with your real demand on-site and your solar generation to create what we call a “Power Point Limit” (PPL) – essentially a maximum limit above which your generation cannot go above if the system is to stay within the site’s regulatory limit.

This value can either be communicated to each individual generation inverter or at an aggregate level to a generation inverter manager that can speak to all inverters at once- applying a whole system limit.

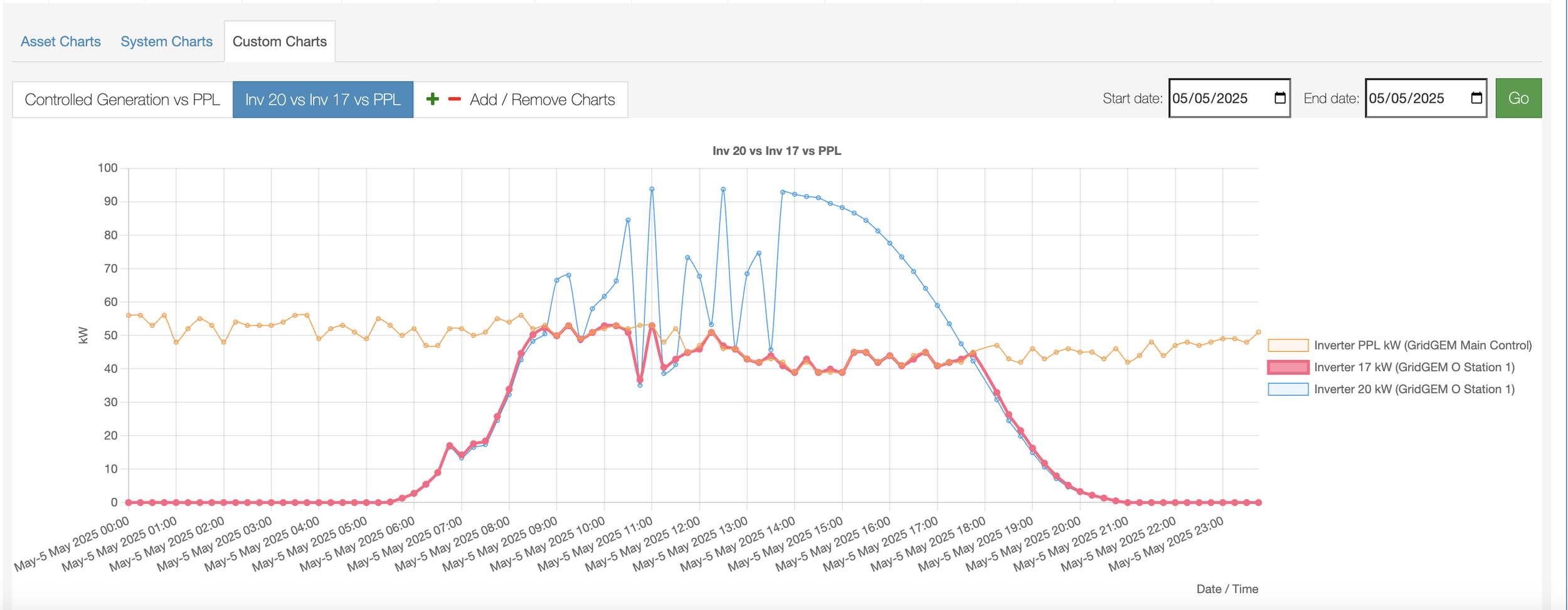

The image below is from an actual client site and helps to explain a number of things:

1. The orange line shows the 15-minute timestamps for the PPL for a specific site for each inverter in kilo Watts (kW). This PPL is, in reality, being updated every 50 mS.

2. The blue line shows the production of an un-limited inverter that is being used to provide a baseline for constraint management at the site – in other words, it is not limited by the orange line.

3. The red line, however, is the production of an inverter that is limited by the system PPL. You can see that it cannot go above the PPL set by the system

This gives rise to a number of interesting elements.

1. G100 Export Limitation Loss Calculation

· If you could have an untethered inverter then this provides a great way to determine the performance of a G100 constrained site

· However, for zero-export sites this is impossible because you can’t have an unlimited inverter that could generate and export if real demand went below its generation level

2. Irradiance Sensors as Standard

· As a result of the above, embedding an irradiance sensor (or similarly, a wind sensor at a wind site) in a system as standard for at least every zero-export limited system should be a valid investment

· Also, in addition, even if you have an unlimited inverter, how do you know that it is performing as it should? Are you comparing limited assets with under-performing assets?

· As such, you could argue that it should be standard for every constrained site to install irradiance sensors to enable one to analyse the real performance and value of curtailed generation

3. Without a Benchmark there’s No Confidence

· A final point is to look at the volatility of production of the unlimited inverter for this one example day

· Without some form of benchmark there is no real way of intuiting the loss of production from constraint management / G100 export limitation

· The requirement for an irradiance sensor (for PV) & / or wind (for turbines) is a valid recommendation

The upshot is that dependent upon the asset being managed under the specific constraint management regulation (G100 etc) a serious asset owner would insist on the installation of a sensor to support the vigorous assessment of performance.

Argand Solutions can embed any sensor required within our constraint management solutions and can also provide the required performance analysis for stakeholders as required.

Give us a call to discuss in more detail.